12 junio 2024

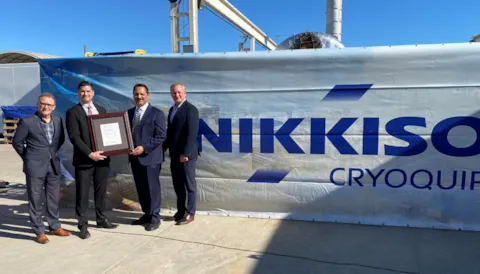

Nikkiso Cryoquip LLC reconoce el papel de DNV en la obtención de la certificación ISO 9001

Cryoquip LLC elogia a DNV por su apoyo excepcional durante la certificación ISO 9001. Como subsidiaria de Nikkiso Co., Ltd., destacan el papel crucial de DNV para asegurar un proceso de certificación ...